Double Block Bleed Forged Steel Class 2500 Trunnion Ball Valve With Self Relieving Vent

TEKO DBB Ball Valves suitable for Oil & Gas production, processing, transportation, distribution, chemical and petrochemical refining including system isolation, pressure level and flow measurement, instrument drain, chemical injection and sampling for smaller sizes.

Usually, there are two types of double block and bleed trunnion mounted ball valves, according to the experience of customer request.

Type 1- a trunnion mounted ball valve in the closed position, provides a seal against pressure from both ends of the valve with a means of vending/bleeding the cavity between the seating surfaces.

According to API 6D “Specification for Pipeline Valves” standards, a double block-and-bleed (DBB) valve is a “single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve, with a means of venting/bleeding the cavity between the seating surfaces.

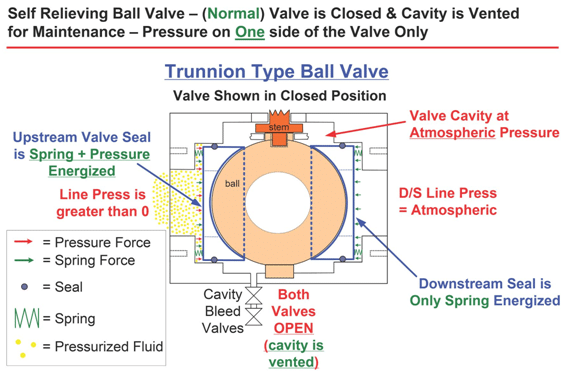

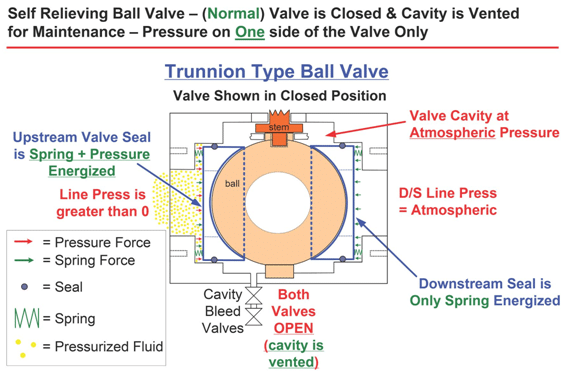

As the definition, a double block and bleed ball valve has two seats, each of the seats provide a seal against pressure seperately. That is to say one seat is sealing the fluid from the upstream and the other seat is sealing the fluid from the downstream. For a trunnion ball valve with double block and bleed, when the valve is in closed position and the fluid comes from the upstream, it pushes the seat against the ball to realize the sealing. The other seat is sealing in the same way.

How does the function of venting/bleeding work? When the pipeline is with pressure, the trunnion ball valve is closed with the fluid trapped in the ball and then there is pressure in the ball. When the temperature in the ball becomes higher, the pressure in the ball will rise too. It is necessary to vent/bleed the pressure in case of risk when the pressure in the ball becomes high enough. For a trunnion ball valve with bleed function, the pressure in the ball pushes the seat back as the spring behind the seat compresses. Then the there is vent/bleeding between the sealing surfaces. Generally speaking, the venting/bleeding is required at the pressure of less than 1.33 times of the design pressure rating for the ball valves as API 6D specifications. Some critical project request to vent/bleed at the pressure of less than 1.1 times of the design pressure rating. (eg. For a PN20 trunnion ball valve, the pressure trapped in the ball shall vent/bleed at the pressure of less than 2.2 Mpa).

Type 2- a trunnion mounted ball valve with two balls and a bleed valves.

These valves have a single body design with double balls with a bleed valve (normally a needle valve or globe valves) installed between the two main line valves. Double block and bleed trunnion ball valves are available bi-directional in metal seated and soft seated style, in bubble tight shut off. Sometimes called twin ball valves. These DBB design valves replace existing traditional techniques employed by pipeline engineers to generate a double block and bleed configuration in the pipeline.

What to look for when selecting a double block and bleed valve?

As with any valve, during selection, one should consider the fluid properties, pressure, temperature. Perhaps most importantly, however, is how the valve will be used. With a number of configurations offered, consider which of these will fit your process and needs best.

If you’re unsure which double block and bleed valve is right for you process, please contact us for help at: sales@teko-valve.com

STANDARD FEATURES

| Construction |

Two or Three piece bolted body |

| Port |

Reduced bore, full bore or fully piggable |

| Stem retention |

Anti blow-out stem |

| Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

| Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

| Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

| Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request)

Metal seated with Tungsten or Chrome Carbide coatings

Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate

Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request

Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request. |

| Drain |

Drilled and threaded connections for all sizes |

| Vent |

Drilled and threaded vent connections for sizes ≥ DN150 (6") < DN150 upon request |

| Stem grease injectors |

Included for all sizes |

| Seat grease injectors |

Included for sizes ≥ DN150 (6"), < DN150 upon request |

| Lifting points |

Included for sizes ≥ DN150 (6") or on valves of 250 kg min |

| Support feet |

Included for sizes ≥ DN150 (6") or on valves of 250 kg min |

| Stem extension |

Not foreseen for this model |

| Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

| Material testing |

Pressure containing & controlling parts to EN 10204 3.1

Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156

Non-destructive testing (NDT) to API 6D, ASME B16.34 |

| Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!